Abstract

A significant challenge for power sources of small-scale quadrotors is the simultaneous need for high gravimetric energy density and high power density. While aluminum–air batteries (AABs) can provide the high energy density, achieving high power density typically necessitates expensive catalysts such as platinum, which can be a significant cost driver. We present microfabricated silver-based air-cathodes for high-power AABs that are suitable for small-scale quadrotor applications. Experimental results, supported by a diffusion–reaction model, indicate that the power performance of the Ag-based cathode is largely determined by the electrochemically active catalyst surface area. To maximize the surface area, we exploit a microfabrication technique involving co-sputtering of a silver–copper alloy on a carbon paper substrate, followed by selective etching of the copper. This process results in a Ag-based paper cathode that delivers a power density of 202 mW cm−2 with 0.3 mg-silver cm−2 catalyst loading. Under battery discharge conditions relevant to small-scale quadrotor operations, the discharge performance of the silver-based AAB is examined. The silver-based cathode achieves a discharge peak power density of 1000 W/kgbattery, which is 70% that of the platinum-based cathode. Notably, when discharging above the 800 W/kgbattery threshold required for the small-scale quadrotor, the silver-based cathode achieves a comparable discharge duration compared with the platinum-based cathode. The cost analysis reveals a significant economic advantage, with this high-power silver-based cathode being 460 times less expensive than the commercial platinum-based cathode on a materials basis.

https://iopscience.iop.org/article/10.1088/1361-6439/add745

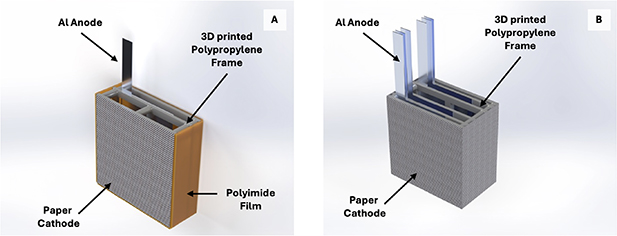

Fig. 1: Schematics of power cells (A) and energy cells (B).