Abstract

Researchers looking for sustainable materials with optimal mechanical properties may draw inspiration from a baseball tradition. For nearly 100 y, a mysterious mud harvested from an undisclosed river site in New Jersey (USA) has been the agent of choice in the USA’s Major League Baseball for “de-glossing” new baseballs. It is unclear, however, what makes this “Rubbing Mud” work. Here, we perform a multiscale investigation of the rheology and tribology of this mud material under baseball-relevant conditions and identify three mechanisms by which the mud alters the surface properties of the baseball. First, the mud creates a more uniform baseball surface by filling in pores in the leather; this is possible because of its relatively high cohesion (clays and organics) making the material remarkably shear thinning. Second, the residue of cohesive particles coating the baseball effectively doubles contact adhesion. Third, a sparse population of angular sand grains are bonded to the baseball by clay-sized particles, leaving a studded surface that enhances friction. The proportions of cohesive, frictional, and viscous elements in Rubbing Mud conspire to create a soft material with an unusual mix of properties, that could find other applications in the development of sustainable geomaterials. Our improved understanding of the flow and friction of natural muds may also find use in modeling natural hazards such as mudslides and for locomotion in muddy environments.

The complexity of soil is the key to its mechanical resilience; soil-based structures can withstand a wide range of stresses due to the multiscale interactions of cohesive agents (such as clay, natural stabilizers, geo- and biopolymers), frictional particles (e.g., sand), and moisture. There is a renewed interest in using locally sourced geomaterials to help meet the UN Sustainable Development Goals for resilient infrastructure and climate action, in view of cement’s carbon footprint and the global sand scarcity (1–3). Witness the expansion of rammed earth construction, which builds on ancient methods that take advantage of soil’s remarkable mechanical and thermal properties (4, 5). A lesser-known tradition is the use of soil-based materials as lubricants and friction agents. Since the 1950s, there has been one substance that every team in North America’s Major League Baseball (MLB) League has applied to baseballs for “de-glossing” and improving grip: Lena Blackburne Baseball Rubbing Mud, commonly called simply “Rubbing Mud” (6). This mud has a storied legacy. In 1938, the eponymous third-base coach of the Philadelphia Athletics discovered the Rubbing Mud in a Delaware River tributary near his home in New Jersey (USA). The precise location has remained a well-guarded secret since then (7). The proprietors have shared only limited information on how the mud is processed after harvesting: it is strained (mesh unknown), skimmed of excess water, rinsed with tap water, given an unspecified “proprietary treatment”, and allowed to settle (duration undisclosed) (8–10). Given the vagaries surrounding Rubbing Mud’s procurement and treatment, and the inconsistency with which it is applied to baseballs, MLB has made several attempts to replace it with “pre-tacked” baseballs. None of these substitutes have been satisfactory, however, leading MLB to issue strict instructions for proper application of Rubbing Mud (8). A natural question then arises: “What does the Rubbing Mud do?” We know of only one peer-reviewed scientific publication, which reported that Rubbing Mud had no significant effect on surface friction (11). In a game so steeped in superstition and tradition, it is unclear whether Rubbing Mud’s effects on the gripping properties of baseballs match pitchers’ beliefs.

It is useful to consider what is generally known about the physics of mud. Although the definition of mud itself is a bit squishy, it is usually considered as a dense suspension of predominantly clay and silt particles in water, with minor amounts of organic matter (12, 13). Sand is often present, but its concentration is small enough that it does not significantly influence flow behavior (12). There are two related but distinct phenomena that are relevant for understanding the Rubbing Mud problem: i) rheology, specifically its yielding and flow behavior under shear, which determines its ability to spread and coat the baseball; and ii) tribology, in particular, the friction and adhesion imparted on the baseball surface once mud is dried. The rheology of mud has been vigorously studied, because of its relevance for natural hazards, such as debris flows (14), and also for dredging and navigation purposes (15, 16). Natural muds, and model muds like clay suspensions (13, 17), are yield-stress materials that exhibit shear-thinning viscosity behavior. The yield stress arises due to interparticle attraction, which forms cohesive aggregates; thus, yield stress increases with both the volume fraction of clay particles and the strength of interparticle bonds (18). When sufficiently sheared, aggregates break up and align with the flow resulting in shear thinning; the viscosity decreases with increasing shear rate. In terms of tribology, there are many studies regarding friction experienced by objects on and in granular substrates due to their importance for biological and robotic locomotion (19); however, these studies have mostly focused on cohesionless materials (sand) (20). Motivated by the problem of dust deposition on solar panels in humid environments, researchers have demonstrated that dried mud increases adhesion and friction of glass surfaces (21, 22). In experiments examining evaporation of polydisperse suspensions, our previous work showed how small particles condense within shrinking capillary bridges—ultimately creating solid bridges of clay-sized particles that bond larger (silt- and sand-sized) particles to surfaces (23).

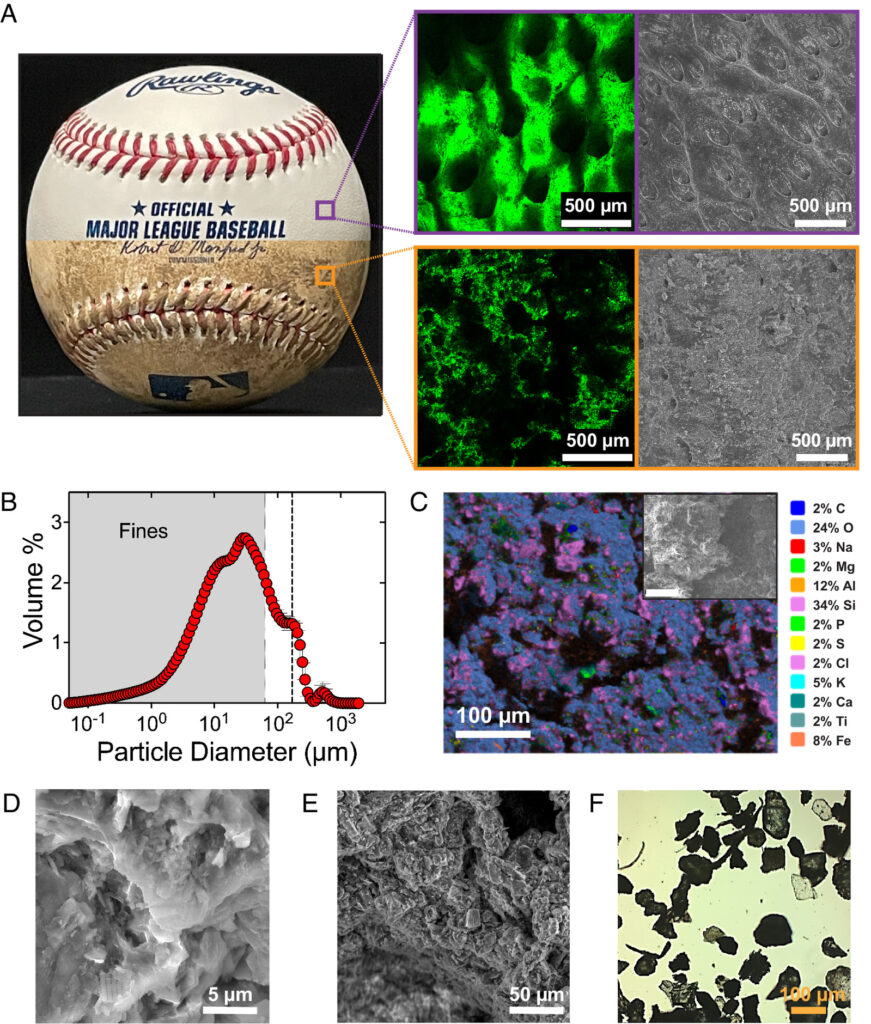

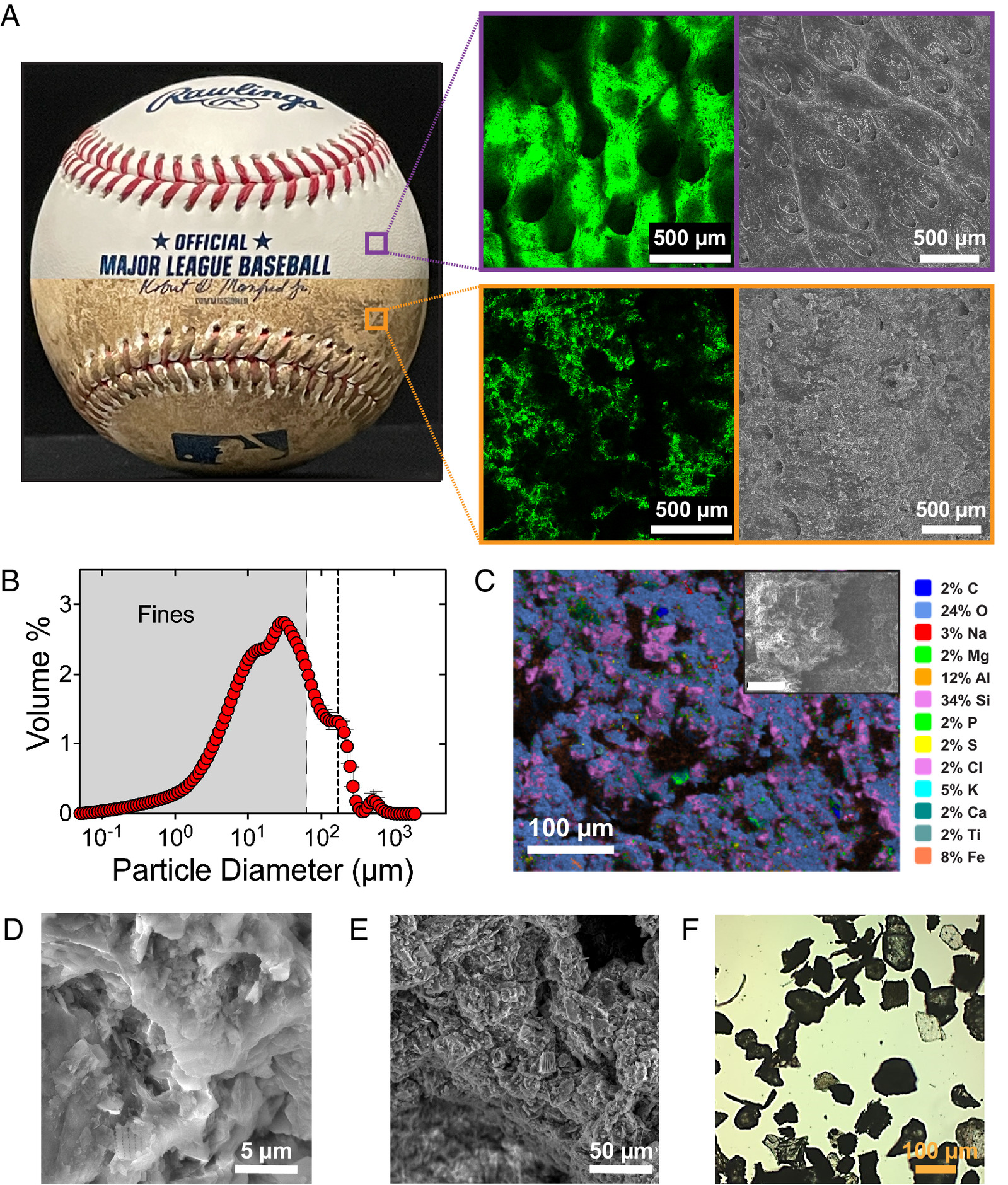

The above studies lead to the following inferences about Rubbing Mud: it has shear thinning behavior that allows it to spread into a thin and uniform coating; its clay and organic content enhances adhesion once applied; and any sand-sized particles may be bonded to the baseball surface by clay-sized particles as the mud dries, leading to increased friction. To test these ideas, here we perform a multiscale experimental approach on Rubbing Mud to characterize its rheology and tribology under conditions that are relevant for baseball application and play. Shear rheometry tests show that Rubbing Mud is a nearly jammed yield-stress material with remarkable shear thinning behavior, akin to a skin cream or polymer melt. Scanning Electron Microscopy (SEM) reveals that the mud coats the baseball uniformly (Fig. 1A), smoothing the surface by filling in holes on the pristine baseball surface. Atomic Force Microscope (AFM) tests demonstrate that dried mud enhances adhesion. A unique soft tribology experimental setup, that mimics human fingers, coupled with microstructural visualization using Confocal Laser Scanning Microscopy (CLSM) show how angular sand grains bonded to the surface increase friction—up to the point that sand grains are sheared off at high sliding speeds. Our observations unravel most of the mystery behind the constituents of Rubbing Mud and its (micro)mechanical functions.

Published in: https://www.pnas.org/doi/10.1073/pnas.2413514121

Figure: Rubbing Mud composition and microstructure. (A) The microstructural visualization of a clean baseball surface (Top) and a mudded baseball (Bottom), using confocal laser scanning microscopy (CLSM) (green images), and scanning electron microscopy (SEM) (gray images). (B) Particle size distribution of Rubbing Mud. The dashed line indicates the suspected mesh size used for the processing of Rubbing Mud; the gray box indicates the range of particles considered “fines” (≤62 μm). (C) Energy dispersive X-ray spectroscopy (EDS) shows a qualitative map of the elements present in Rubbing Mud smeared on a baseball; the Inset shows SEM image of the same area as the EDS map. SEM images of clay sheets and silt particles that contribute to the (D) tail and (E) the peak of the particle size distribution. (F) Optical microscopy of angular sand grains and silt-size particles with plant detritus that correspond to the coarse fraction.